Last Updated on June 10, 2024 by teamobn

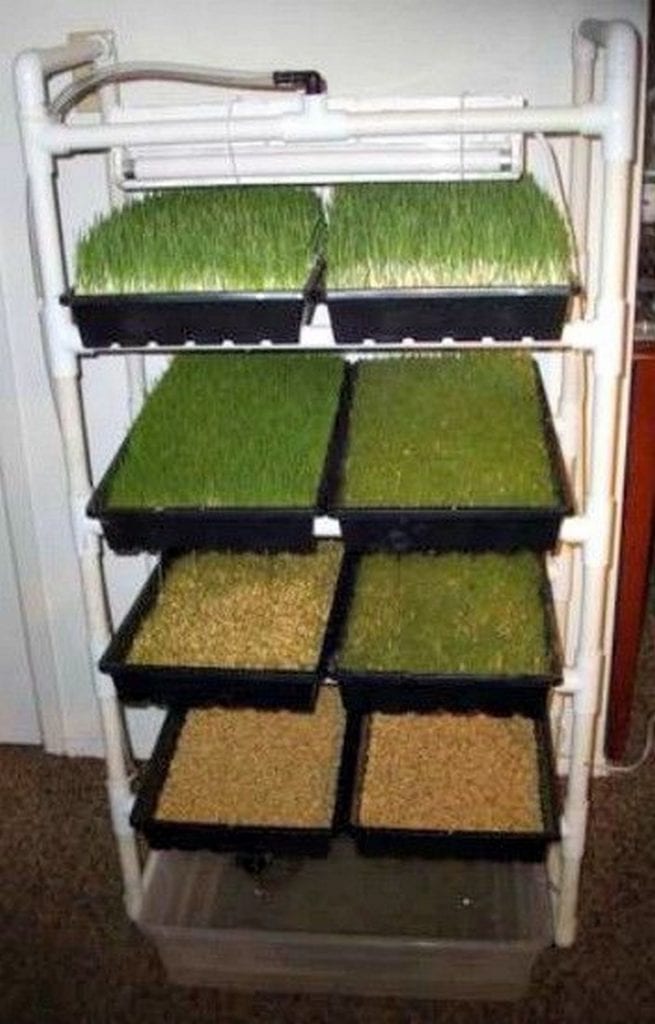

Growing fodder for livestock is a nutritious and economical way to feed your homestead animals. It doesn’t have to be huge. A small-scale system can actually work well, depending on the number of animals you need to feed. This is very useful especially if you live in areas with very long winters.

The best thing about fodders is that they grow very quickly. You can have ready-to-feed fodder in as little as six to eight days. Additionally, nothing is ever wasted as the animals eat everything – seeds, sprouts, and roots!

A huge fodder system can cost thousands of dollars. But why spend that much money when you can make your own?

Building a Fodder Systerm

Contents

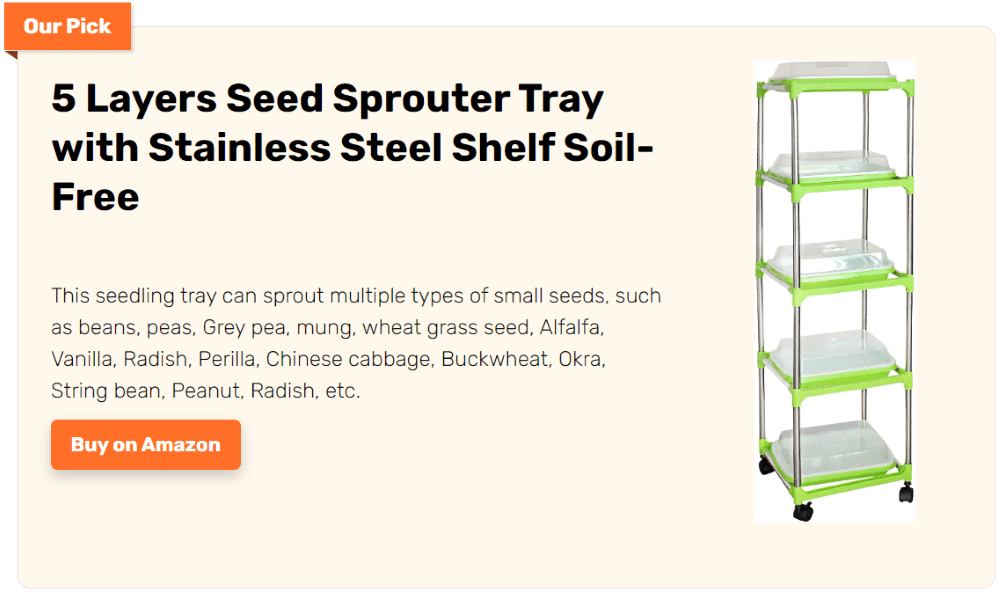

Materials

- Wood

- Screws

- Trays/Drawers

- Wood filler

- Stain

Tools

- Knife

- Measuring tape

- Pencil

- Miter saw

- Orbital Sander

- Drill with drill bits

- Router

Instructions

Step 1: Design Your System

- Use a pencil and measuring tape to plan the dimensions of your fodder system. Consider how many trays you want and the overall space you can dedicate to the system.

- Sketch a simple blueprint that includes shelves to hold the trays or drawers.

Step 2: Cut the Wood

- Using the miter saw, cut your wood according to the measurements from your blueprint. Ensure all pieces are correctly sized for shelves, supports, and the frame.

Step 3: Assemble the Frame

- Begin assembling the frame by aligning the cut pieces. Use the drill and screws to secure the pieces together, ensuring the structure is sturdy and level.

Step 4: Prepare and Install Shelves

- If you’re using drawers, ensure they fit into the frame. If using trays, cut additional wood to create shelf supports inside the frame where trays will rest.

- Secure the shelves or drawer supports with screws.

Step 5: Sand the Wood

- Use the orbital sander to smooth all surfaces of the wood, preventing splinters and ensuring a clean finish for the stain.

Step 6: Apply Wood Filler

- Fill any gaps or screw holes with wood filler for a seamless look. Allow the filler to dry according to the product’s instructions.

Step 7: Stain the Wood

- Apply stain to all exterior and visible surfaces of the wood frame. Use the brush evenly, and follow the wood grain. Allow the stain to dry completely.

Step 8: Install the Trays/Drawers

- Place the trays or drawers into the system. If they are removable, ensure they slide in and out smoothly.

Step 9: Set Up the Fodder Growing Area

- Prepare each tray or drawer by adding a layer of seeds suited for fodder growth (commonly barley, wheat, or alfalfa).

- Initially, water the seeds to start the germination process.

Step 10: Daily Maintenance

- Water the seeds daily, ensuring they are moist but not waterlogged.

- Monitor growth and adjust conditions like light or water as necessary to optimize fodder development.

Step 11: Harvesting

- Once the fodder is fully grown (typically within 6-8 days), harvest by removing it from the trays. The roots, seeds, and sprouts are all edible for livestock.

Click on any image to start the lightbox display. Use your Esc key to close the lightbox.

If you want to learn how to build a fodder system for your livestock, watch this video.

Benefits of Fodder Systems for Various Types of Livestock

Fodder systems offer an efficient and sustainable method of providing fresh, nutrient-rich feed to various types of livestock. These systems are particularly valuable for optimizing animal health and improving feed efficiency across different farming environments. Here’s how a fodder system benefits specific livestock groups:

Benefits for Cattle

- Nutrient-Rich Diet: A fodder system provides cattle with fresh greens that are high in essential nutrients like proteins, vitamins, and minerals, which can improve milk yield and quality in dairy cows and increase weight gain in beef cattle.

- Improved Digestion: The sprouts and greens from a fodder system are easier for cattle to digest compared to dry hay. This can lead to better overall health and reduced instances of digestive disturbances.

Benefits for Poultry

- Enhanced Egg Production: Chickens fed with greens from a fodder system typically produce eggs with richer yolks and stronger shells. The high nutrient content, especially in vitamins, enhances the overall quality of the eggs.

- Better Health: The fresh feed helps boost the immune system of poultry, reducing the need for antibiotics and leading to healthier, more robust birds.

Benefits for Sheep and Goats

- Cost-Effective Feeding: Fodder systems can reduce feed costs significantly for sheep and goat farmers, as they can provide a large volume of feed at a low cost, especially during winter when other greens might be scarce.

- Quality Wool and Meat: Feeding sheep and goats with high-quality fodder results in better wool quality due to improved nutrition, and in goats, it enhances meat quality as well.

Benefits for Horses

- All-Year Feed Availability: A fodder system ensures that horses have access to fresh greens throughout the year, which is particularly beneficial in areas with seasonal pasture shortages.

- Enhanced Performance and Stamina: The improved nutritional content helps in maintaining higher energy levels and better overall health, which is crucial for performance horses.

Implementing a fodder system can provide these benefits to various types of livestock, making it a versatile and valuable addition to farm management practices. By incorporating a fodder system, farmers can ensure a consistent, controlled, and clean source of nutrition for their animals, leading to healthier livestock and more sustainable farming operations.

Comparing Hydroponic vs. Traditional Fodder Systems

Fodder systems are an innovative solution for feeding livestock, providing fresh, nutrient-rich feed year-round. These systems come in two main types: hydroponic and traditional. Each has its unique set of benefits and drawbacks, making them suitable for different farming needs and environments.

Here’s a detailed comparison to help you decide which system might be best for your needs.

Hydroponic Fodder Systems

- Water Efficiency: Hydroponic fodder systems use water as the growing medium, eliminating the need for soil. This results in up to 90% more water efficiency compared to traditional methods.

- Space and Speed: These systems require less space and can produce fodder faster, typically within 6 to 8 days from seeding to harvest. This makes them ideal for operations with limited space.

- Control Over Environment: Hydroponic systems allow for greater control over the growing environment, including temperature, humidity, and light. This control can lead to higher yields and less susceptibility to external weather conditions.

- Initial Cost and Maintenance: The main drawback is the higher initial setup and maintenance costs. Hydroponic systems also require more technical knowledge to manage the nutrient solutions and system components effectively.

Traditional Fodder Systems

- Lower Startup Costs: Traditional fodder systems involve growing fodder in soil, which generally has lower startup costs compared to hydroponic systems. They are simpler in design and easier to implement with basic farming tools.

- Simplicity and Accessibility: These systems are often more accessible to farmers with traditional farming knowledge and do not require electricity or complex machinery, making them suitable for remote or rural areas.

- Dependence on Soil Quality and Climate: The success of traditional systems heavily depends on the quality of the soil and local climate conditions. This can make them less predictable and potentially more labor-intensive to manage.

- Greater Space Requirements: Traditional systems typically require more space than hydroponic systems, as the fodder needs more area to spread its roots in the soil. This might not be ideal for farms with limited land.

Choosing between a hydroponic and a traditional fodder system depends largely on your specific farm’s needs, budget, and available resources. Hydroponic systems offer efficiency and control but at a higher cost and complexity. Traditional systems are cost-effective and straightforward but require more space and are subject to environmental variables.

Each system has its place in modern agriculture, and the right choice will depend on aligning the system’s features with your farming objectives. By carefully considering these factors, you can maximize the benefits of your chosen fodder system.

Troubleshooting Common Problems in Fodder Systems

Fodder systems are an efficient way to provide fresh, nutrient-rich feed to livestock, but like any agricultural method, they can encounter specific challenges. Addressing these issues promptly can help maintain the productivity and effectiveness of your fodder system.

Here’s a guide to troubleshooting common problems that may arise.

Mold Growth

Problem: Mold can develop due to excessive moisture and poor air circulation. It’s harmful as it can contaminate the fodder, making it unsafe for livestock.

Solutions:

- Ensure proper ventilation in the growing area to reduce humidity levels.

- Monitor and adjust watering schedules to avoid over-watering.

- Clean trays and equipment regularly with a natural antifungal solution to prevent spore buildup.

Uneven Germination

Problem: Seeds may not sprout uniformly, leading to patches of underdeveloped plants, which affects the overall yield.

Solutions:

- Use high-quality, fresh seeds with high germination rates.

- Ensure even distribution and adequate soaking of seeds before planting.

- Check for consistent moisture and temperature throughout the growing area.

Slow Growth Rate

Problem: Fodder growing slower than expected can be due to inadequate nutrients, incorrect temperature, or insufficient light.

Solutions:

- Test and adjust the nutrient solution strength if using a hydroponic system.

- Maintain the growing area at optimal temperatures suitable for the specific type of fodder being grown.

- Provide supplemental lighting if natural light is insufficient, especially in shorter daylight periods.

Root Mat Issues

Problem: Poor root development can affect the stability and nutrient uptake of the plants, leading to weaker yields.

Solutions:

- Ensure the base of the growing trays has adequate drainage to promote healthy root growth.

- Consider a medium that supports better root spread and aeration.

- Check that the water pH is suitable for plant growth, adjusting as necessary.

Pest Infestations

Problem: Pests such as aphids or mites can infest fodder systems, especially in warm, humid environments.

Solutions:

- Implement regular inspections and early detection practices to catch infestations early.

- Use organic pesticides that are safe for both the plants and livestock.

- Improve hygiene and reduce potential infestation sources by keeping the fodder area clean and free of debris.

By effectively managing these common issues, you can ensure that your fodder system remains a reliable and productive component of your livestock feeding regimen. Regular maintenance and observation are key to catching problems early and keeping the system running smoothly.

Conclusion

Creating a fodder system is an economical and environmentally friendly method of feeding your animals fresh, wholesome feed. It is possible to guarantee consistent yields and a dependable feed source all year round with meticulous planning and upkeep. This do-it-yourself method improves your animals’ general health and productivity while also cutting feed expenses.